Reactive Fabric Printing Technology Introduction

Reactive Fabric Printing Technology Introduction

Model NO: Reactive fabric printing

Process Overview:

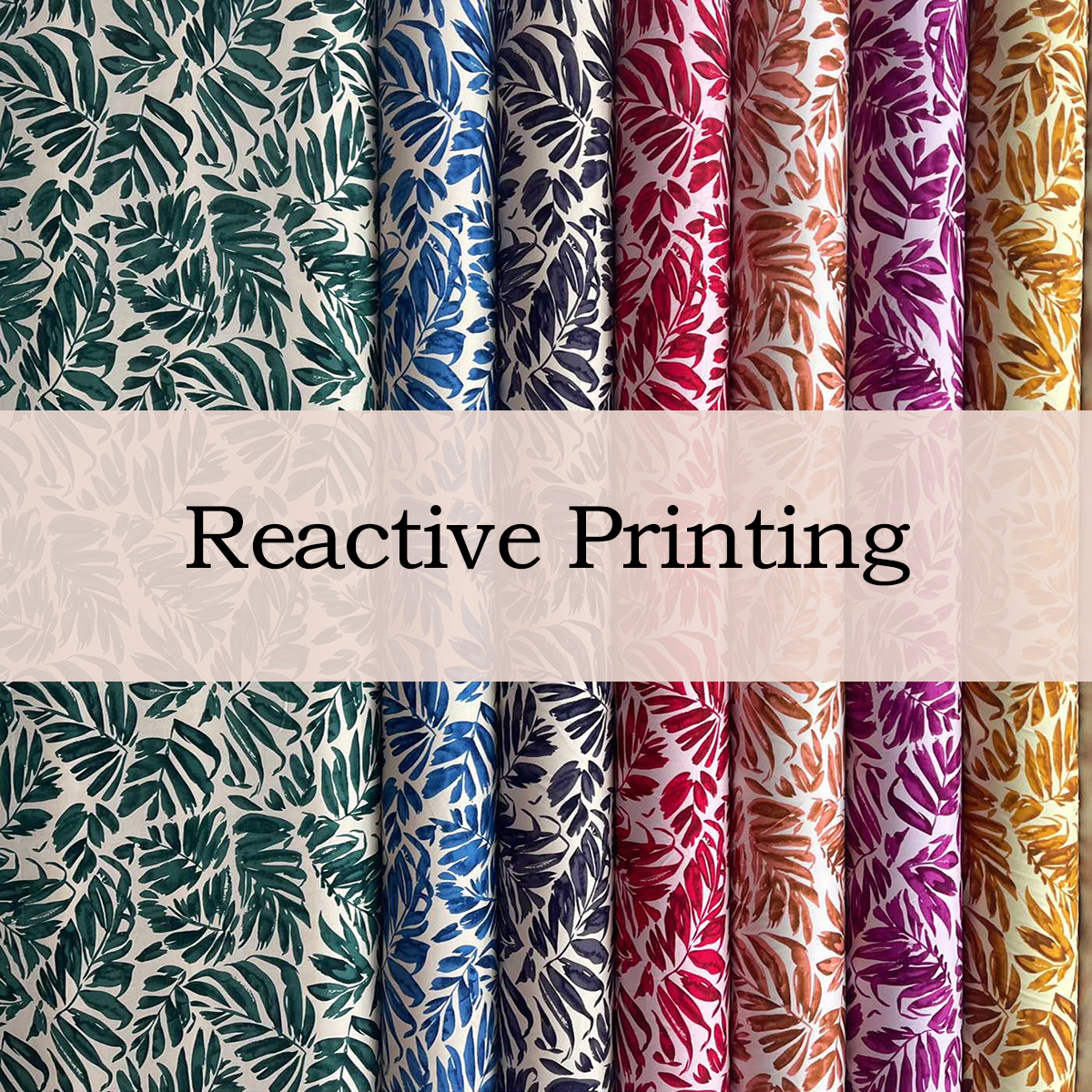

Reactive fabric printing is a technique primarily used on cellulose-based fibers such as cotton, linen, silk and viscose. It uses reactive dyes that form a chemical bond with the fiber, producing bright, vibrant, and long-lasting colors. During the process, the dye is applied to the fabric through methods like screen printing or digital printing, followed by steaming or heat fixation to ensure the design is fixed firmly while keeping the fabric soft and comfortable.

Advantages and Limitations:

This method offers excellent color brightness, sharp pattern definition, and high wash and light fastness, making it ideal for detailed and complex designs. Its limitations include sensitivity to incorrect fixation conditions, a need for precise handling during steaming or washing, and suitability mainly for cellulose fibers, making it less effective on synthetic fabrics like polyester or nylon.

Ideal Applications:

-

Cotton: t-shirts, dresses, shirts, casual wear

-

Linen: table linens, curtains, summer apparel

-

Viscose: scarves, blouses, lightweight garments

-

Silk: scarves, silk shirts, silk dresses

Working With Facto Textile

We promise you:

- A wide variety of high- quality fabrics

- Full range of customized services

- Professional production technology

- Sincere Cooperation

Contact Us To Start Your Fabric Project

Please send us your message, we will reply within 20 hours.