Dyeing Factory

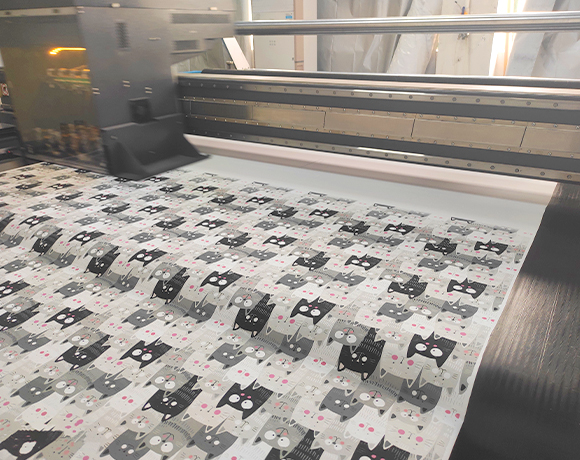

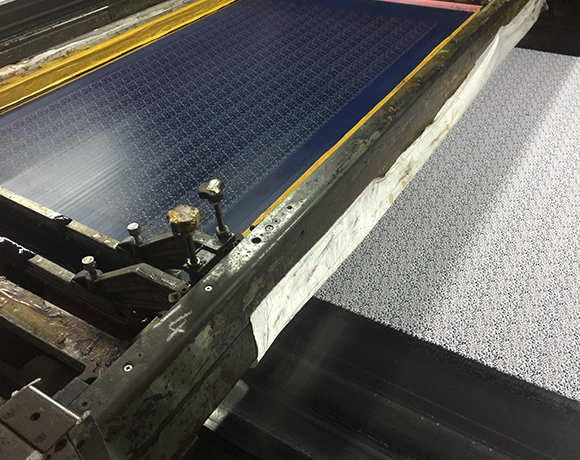

We are proud to operate our own dyeing factory, which gives us complete control over the quality and consistency of every fabric we produce. Unlike many suppliers who rely on third-party factories, our in-house dyeing workshop offers greater flexibility, faster turnaround, and strict compliance with international standards.

Our dyeing process combines advanced equipment with skilled craftsmanship to achieve precise color matches, vibrant shades, and long-lasting durability. Whether you need classic colors or fully customized shades, we can reproduce exact results with outstanding accuracy. By fully overseeing the entire process, we minimize defects, shorten lead times, and ensure that every fabric meets our customers’ expectations.

Environmental responsibility is also at the core of our dyeing operations. We apply eco-friendly techniques and strictly follow recognized standards for wastewater treatment and chemical safety. This commitment not only helps protect the environment but also gives our partners the assurance that the fabrics they purchase meet the growing demand for sustainable production.

As a trusted fabric manufacturing company, Factotex is committed to supporting global fashion brands, home textile makers and creative design studios with fabrics that perform beautifully and inspire creativity.